How Thermal Spray Powder Morphology Impacts Coating Performance

Thermally sprayed coatings are some of the best surface engineering solutions in enhancing the lifetime and performance of equipment that is exposed to high temperatures, and highly corrosive and wear-prone environments. The target applications range from tiny electronics to large gas turbines and windmills. These coatings can possess high thermal and electrical insulation as well as superior wear and abrasion resistance.

The coatings are applied through the use of thermal spray technology. The solid, semi-molten, or molten thermal spray powder is deposited via spray torches on target surfaces at extremely high speeds and elevated temperatures. The molten thermal spray powder flattens upon impact and forms successive, lamellar-like splat layers which solidify as coatings.

The thermal spray powder used for coating directly impacts the coating’s chemical, mechanical and thermal properties. Therefore, you should choose the thermal spray powder of optimum morphology and chemistry to achieve a consistent coating structure.

The powder morphology plays a key role mainly on two fronts: first, the efficiency of the feeder, pipeline, and injection systems, and second, the deposition and coating build-up mechanisms.

Impact on Feeding and Injection Systems

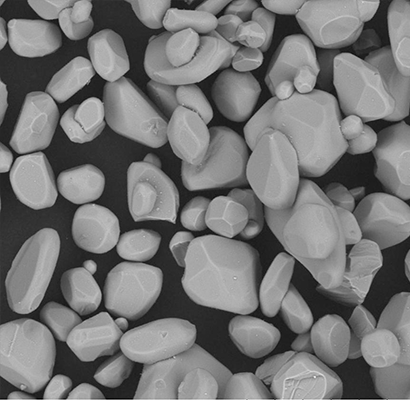

Thermal spray powders containing spherical particles have improved flow characteristics and delivery rates due to single-point contacts, unlike angular particles with planar faces. Angular particles are more likely to clog the feeder and injection system. Consequently, the irregular feed rate of thermal spray powder results in a heterogeneous coating resulting in substrate overheating and potential coating delamination. Spherical particles are less abrasive, and therefore, yield low wear of feeding systems and minimal contamination of coatings via impurities. Thermal spray powder containing spherical particles has a lower potential to react with hot gases due to their lower surface-to-volume ratio, thereby reducing impurities and voids in the resulting coating.

Impact on Coating Microstructure

Porosity comprises the most common microstructural defects in thermally sprayed coatings that can eventually lead to coating failure. The particles that do not melt attach to the target substrate and form voids. Thermal spray powders with hollow sphere morphology and crushed particles ensure complete melting, eventually leading to higher deposition rates, reduced porosity, and a smooth surface finish.

Spherical particles have a high aspect ratio and a smaller specific surface area. Beyond a critical size, particles do not completely melt in-flight and tend to rebound off the substrate, resulting in a lower deposition efficiency. Partially melted particles do not flatten thoroughly into a lamellar structure and reduce the coating adhesion with the substrate. Large non-melted particles could also lead to large protrusions and conical defects in the coatings.

Thermal spray powders with hollow spheroidal particles tend to melt more than crushed and fused angular particles, undergoing severe plastic deformation upon impact with the substrate. This results in a coating having thinner lamellae and a high density of inter-splat boundaries, which ultimately lowers the coating’s thermal conductivity. Irregular, angular particles gain higher velocities during thermal spraying due to higher drag forces but have lower temperatures than spherical ones. However, thermal spray powders that melt partially can be utilized to achieve partial nanostructured coatings with a desired nanostructured core.

A homogeneous thermal spray powder possessing fewer impurities ensures a high sintering resistance of the coating. Saint-Gobain’s yttria, yttria zirconia, and spinel-based thermal spray powders are a few examples of very high-temperature thermal barrier applications.

Thick coatings require thermal spray powders with coarser particle morphology, whereas fine particles are used to produce thinner coatings. For applications that require thick coatings, thermal spray coatings that contain coarser particles are the ideal prescription.

More open and irregular morphologies are preferred for applications that demand corrosion resistance in severely acidic and caustic environments and high wear resistance against fretting and cavitation. These coatings are dense, hard and deposited using thermal spray powders having fused and crushed, irregular, blocky-shaped morphology such as those based on zirconia, aluminum oxide, aluminum silicate, and aluminum titanate.

Want to learn more? Read our Introduction to Thermal Spray Technology

Saint-Gobain offers thermal spray powders with tailored particle morphologies and chemistry to cater to our customer’s needs. To learn more about our wide range of thermal spray powders, contact our team today.

References:

L. Feng et al., Effect of powder particle size on microstructure and properties of low pressure cold sprayed high aluminium bronze coating, Mater. Res. Express 7 (2020) 026524. Available at: https://iopscience.iop.org/article/10.1088/2053-1591/ab6fac/pdf

A. Nouri et al., Powder morphology in thermal spraying, J. of Adv. Manuf. Process. 1 (2019) e10020. Available at: https://aiche.onlinelibrary.wiley.com/doi/epdf/10.1002/amp2.10020