The Evolution of Flame Spray Technology

Flame spraying is one of the oldest and simplest ways of depositing a metallic or ceramic coating onto a surface. However, thanks to its versatility and cost-effectiveness, it remains the most widely-used thermal spraying technique today. Here we cover the fundamentals of flame spray technology and take a look at some of the most common flame spray applications.

History of Flame Spray Technology

The flame spray process was first developed in the early 20th century by Swiss engineer Max Ulrich Schoop. In an effort to create protective coatings, Schoop used a combustion heat source to melt lead or zinc wires. A high velocity flow of air or inert gas over the molten wires atomized the metals and sprayed them toward the substrate, creating a durable protective layer.

Following its initial development, flame spray technology was rapidly adopted in Germany and the USA throughout the 1920s and 1930s. Our pedigree in flame spraying was born during this time at the Société Nouvelle Métallisation (SNM) in Paris, which opened a branch in Avignon in the mid-20th Century. Saint-Gobain purchased the site in 1998 and have been expanding the flame spray capabilities ever since.

A key driver of the new technology was that it enabled the restoration of industrial machinery: the flame spray process could undo damage caused by cavitation and give all manner of rods, shafts and drums a new lease of life. Soon, the flame spray process was adopted into manufacturing, where it provided protective coatings to automotive components. Other early applications included lead coatings for light bulbs, and protective aluminum coatings for vehicle and aircraft manifolds.

Flame Spray Fundamentals

The flame spray process belongs to a group of processes known collectively as thermal spraying. Thermal spraying techniques all work by heating a feedstock material, usually in the form of powder or wire, then propelling it towards a substrate. Molten or partially molten droplets of the feedstock material form “splats” known as lamellae on the substrate, which accumulate to form a uniform coating.

Thermal spraying processes can be broadly categorized according to how they provide thermal energy to the feedstock material. As implied by the name, flame spray processes do so using a flame: The combustion of a gas (usually acetylene or propane) and oxygen heats the feedstock material up to a maximum temperature of around 2100 K, while accelerating droplets up to a maximum velocity of around 150 m/s.

Benefits of Flame Spray Coating

Compared to other thermal spray processes like HVOF and plasma spraying, flame spraying has a relatively low operating temperature and produces low droplet speeds. These process conditions do place some limitations on the materials that can be deposited; and other thermal spraying processes can produce higher quality coatings. However, the cost effectiveness and ease of the flame spray process mean it remains the most popular thermal spray process today.

As the simplest thermal spray method, flame spraying is generally the cheapest way of depositing a protective metallic or ceramic coating. Because flame spraying is generally carried out by hand, it is well-suited to components with irregular or complex geometries. Flame spraying equipment is typically portable and easy to use, and eliminates the need for mechanical manipulators for most applications.

Applications and Materials

The quality of flame spray coatings is sufficient to meet the needs of a wide range of protective applications. Flame spraying is still widely used for reclamation of worn shafts and other mechanical equipment, and for protecting structures and components against corrosion.

A wide range of materials including aluminum, bronze, low-carbon and stainless steel, molybdenum and zinc can all be deposited via flame spray. With our equipment, high-quality ceramic and carbide coatings can also be produced using our proprietary Flexicord products and Rokide rods.

Flame Spray Solutions from Saint-Gobain

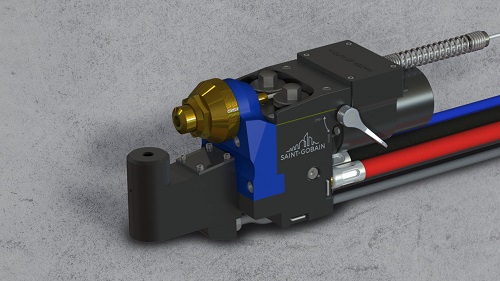

At Saint-Gobain, we apply our materials science and processing expertise to develop high-performance equipment and materials to suit any coatings applications.

View our range of flame spray guns or get in touch with us today to find out more.